Cut the Noise.

The global customer's first choice for EMI and EMC solutions

Cut the Noise.

The global customer’s first choice for EMI and EMC solutions

Efficiency is not a milestone. It is a continuous process, changing as per newer technologies and environments. At EMIS, we do not stop once a great product is created. We are constantly testing and building efficiency for the ever-evolving world.

Delivering Efficiency across Industries

Delivering Efficiency across Industries

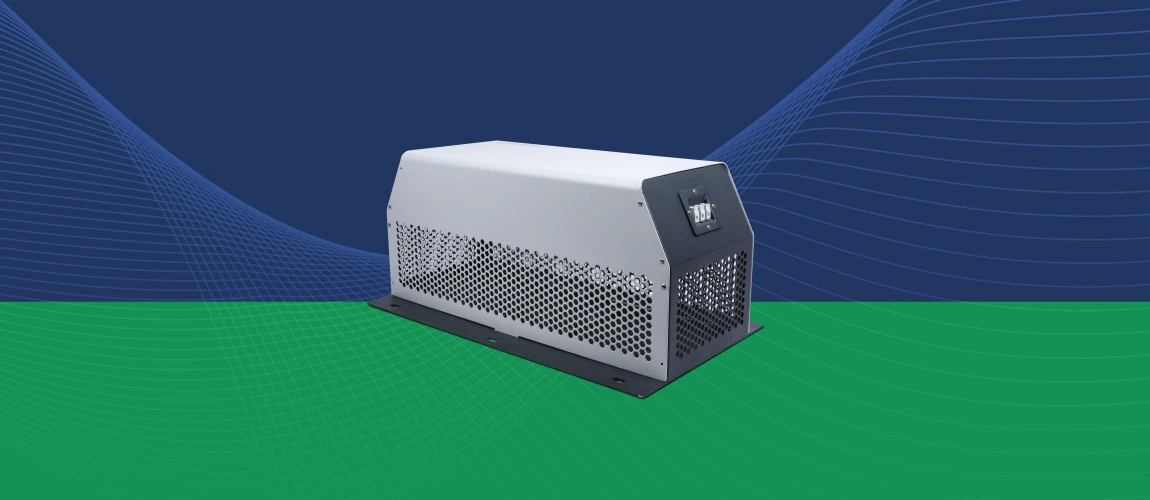

Precision, across the Spectrum

Solving EMI Challenges ranging from 50 Hz to 40 GHz

Services

Scientific solutions that are relevant and adaptable to the evolving requirements and environments

Specifications

Know more

Know more

Building Exactitude

for World Leaders

News & Insights

EMI Filters for VFD Applications

What is EMI? Electromagnetic Interference or EMI also commonly called

Brief guide on what are AC Line Reactors & when is it used

The Line Reactors are also called as Line Chokes or Inductors; Lin

Passive Harmonic Filters for Inverters – Three Phase Passive harmonic filters from EMIS

AC motors used in industrial environments are connected to an inverter

DC EMI Filters for Interference and Combat Applications – EMIS

Does DC generate EMI? Why do we need EMI filters for equipment running

Our Global Reach

3 Continents | 14 Countries

Asia

India, Israel, Malaysia, Singapore, Thailand, Vietnam

Europe

France, Germany, Italy, Netherlands, Sweden, Spain, Switzerland, UK

America

USA